RADIOGRAPHIC TESTING

WHAT IS RADIOGRAPHIC TESTING?

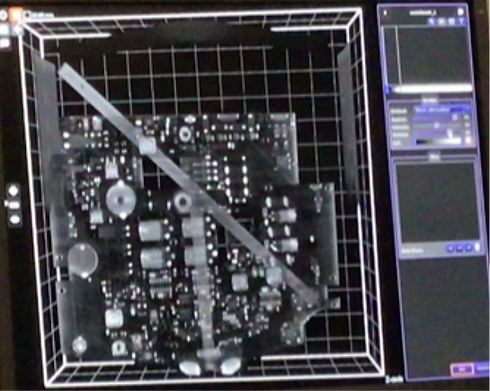

Radiographic Testing is a traditional non-destructive testing (NDT) method that examines the volume of a specimen and the internal structure of a component to identify any flaws or defects without damage. Radiography (X-ray) uses X-rays and Gamma-rays to produce a radiograph, showing any changes in thickness, defects, and assembly details to ensure optimum quality in your operation.

It is used in a variety of materials and it has many advantages since it requires very little surface preparation, it is portable which allows for use in the field and elevated positions, its versatility in detecting a wide range of defects on multiple materials and its ability to produce a permanent record of the inspection.

This technology is widely used to inspect machinery, piping, forgings, valves, pressure vessels, valves and weld joints, castings and composites. It detects porosity, inclusions, cracks and voids.

WHY I SHOULD CONSIDER A CAREER IN RADIOGRAPHIC TESTING

In general NDT plays a vital role in various industries as stated before so you can become employable. There is an increasing need for nondestructive testing so there are plenty of opportunities for all skill levels for technicians and professionals.

RT is a technical career with a lucrative path with plenty room for advancement. Employers usually look for technicians and professionals with formal education on the topic to ensure quality, safety and reliability.

Being updated in this career is a necessity. You must be qualified for working in this field. This is because errors in this industry can have disastrous consequences. In MR&T we are proud to have the latest trends and updates in the norms, standards, and procedures, combined with our ability to teach in a way that you will be totally prepared.

RADIOGRAPHIC TESTING - LEVEL I (RT1)

The RT-1 course will provide you with the basic theory and practical knowledge about radiographic inspection. You will learn all about welding processes and weld defects, as well as key concepts to apply this in welding processes and weld defects. Also we will cover properties of XRay and GammaRay, film selection, film processing, the necessary equipment, hazards, regulations, quality issues and reporting.

WHY SHOULD I STUDY RT-1?

This course is designed for people interested in making a career in Radiographic Testing and Inspection. It is intended for operators, inspectors and technicians responsible for practical application of testing, inspection and writing techniques and instructions for detection of flaws in various types of material across all industry sectors.

RT-1 is your first course in your career path. RT Positions even at entry-level generally require specialized training. Also the career growth in the future looks bright for RT professionals since the NDT industry will continue to grow substantially. There’s unlimited room for advancement.

WHAT WILL I LEARN IN RT-1?

RT1 Students will learn basic and key concepts regarding testing and inspection processes in relation to radiographic testing.

We will cover in detail the following topics:

-

Introduction

-

Fundamental Properties of Matter

-

Radioactive Materials

-

Types of Radiation

-

Interaction of Radiation with Matter

-

Exposure Devices and Radiation Sources

-

Radiographic Safety Principles Review

-

Process of Radiography

-

Types of Electromagnetic radiation Sources

-

Xray tube

-

Principles of Radiography

-

Radiographs

-

Radiographic Image Quality

-

Film Handling, Loading and Processing

-

Exposure Techniques - Radiography

-

Fluoroscopic Techniques

-

Digital Radiography

-

Introduction

-

Fundamental Properties of Matter

-

Radioactive Materials

-

Types of Radiation

-

Interaction of Radiation with Matter

-

Exposure Devices and Radiation Sources

-

Radiographic Safety Principles Review

-

Digital Radiography Overview

-

DR System Components

-

Image Fidelity Indicators

-

Detector Issues

-

Technique Issues

-

WHAT WILL I BE ABLE TO DO AFTER TAKING THE CLASS?

-

Understand and explain the basic principles and theoretical background of the method and the specific radiographic techniques.

-

Be able to explain the specific requirements for the technique.

-

Be familiar with the different procedures involved in the method and the parts tested.

-

Explain the benefits of using this technique as well as the disadvantages of the test method.

-

Demonstrate competence in basic inspection by detecting and characterizing flaws in components.

-

Perform radiographic inspection tests in metals, plastics and composites.

-

Be aware of the different types and products available in the industry for this method and be able to select the proper equipment and settings for each test.

-

Use the XRay and Gamma Ray technique in locating discontinuities following authorized testing procedures.

-

Follow the instructions given by Level 2 and Level 3 professionals.

-

Be able to explain the safety precautions required using this method.

-

Be able to prepare a report showing the test results.

-

Set up and calibrate RT equipment and decide on necessary items required to complete the job.

RADIOGRAPHIC TESTING - RT LEVEL II

This course is designed for professionals interested in continuing their career in Radiographic Testing and Inspection. It is intended for operators, inspectors and technicians responsible for practical application of testing, inspection and writing techniques and instructions for detection of flaws in various types of materials across all industry sectors. At this level Level 2 professionals would be more independent and be able to perform and supervise tests, as well as all prepare and setup of the equipment. Also they will be able to prepare, interpret and evaluate results.

Why should I study RT-2?

This course is designed for professionals interested in continuing their career in Radiographic Testing and Inspection. It is intended for operators, inspectors and technicians responsible for practical application of testing, inspection and writing techniques and instructions for detection of flaws in various types of material across all industry sectors. At Level 2 professionals could be more independent and perform and supervise tests, as well as prepare and setup the equipment. Also they will be able to prepare, interpret and evaluate results.

RT-2 is your intermediate course in your career path and is designed for those technicians who wish to progress their career into cutting edge RT method. It is intended for experienced technicians and engineers who are able to set up and calibrate testing equipment, conduct the inspection according to the standards and report. Usually they supervise and train Level 1 technicians.

WHAT WILL I LEARN IN RT-2?

RT2 Students will learn the procedures of inspection techniques in detail, produce written instructions, record and report defects.

We will cover in detail the following topics:

-

Film Quality and Manufacturing Processes

-

Review of Basic Radiographic Principles

-

Darkroom Facilities, Techniques and Processing

-

Indications, Discontinuities and Defects

-

Manufacturing Processes and Associated Discontinuities

-

Radiographic Safety Principles Review

-

Radiographic Viewing

-

Application Techniques

-

Evaluation of Castings

-

Evaluation of Weldments

-

Digital Radiography Technique Course

-

Basic DR versus Film Principles

-

DR System Components

-

Image Fidelity

-

Image Processing (Post-Processing)

-

Detector Issues for the Dectector(s) Used

-

Detector Calibrations for the Detector(s) Used

-

Monitor and Viewing Environment

-

Technique Development Considerations

-

Detector Monitoring

-

Detector Maintenance

-

Use of Digital Reference Images

-

Radiographic Safety Principles Review

-

-

Evaluation and Interpretation

-

Image Viewing

-

Application Techniques

-

Evaluation of Castings

-

Evaluation of Weldments

-

Standards, Codes, and Procedures for Radiography

-

WHAT WILL I BE ABLE TO DO AFTER TAKING THE CLASS?

-

Be aware of the different types of equipment and products available to industry with regards to radiation methods to select the proper ones to perform each specific test. Define the limitations of application of the testing method.

-

Set up and calibrate RT equipment.

-

Review work that has been done by Level 1 technicians.

-

Explain the theoretical background of the Method and the specific radiographic techniques.

-

Explain in detail the advantages and disadvantages of the radiographic test method.

-

Demonstrate competence by detecting and characterizing flaws in components

-

Perform radiographic inspects in metals, plastics and composites and translate NDT procedures into instructions adapting them to the actual working conditions.

-

Use the Xray and Gamma ray technique in locating discontinuities.

-

Supervise all tasks at, or below level 2.

-

Report the results of non-destructive tests and be able to interpret performance results according to applicable standards and procedures.

-

Write inspection procedures to be reviewed and approved by the Level 3 professional.

-

Understand and recognize the surface and sub-surface discontinuities, flaws or irregularities.

-

Understand and review the safety precautions required for radiation hazards.

RADIOGRAPHIC TESTING TRAINING - RT LEVEL III

The RT Level 3 provides a comprehensive understanding of the RT theory and in-depth experienced practical knowledge at an advanced level. It prepares students to perform radiographic inspection and provide guidance to NDT personnel at all levels. The student will learn thoroughly concepts, mathematical relationships and will be very knowledgeable about the terminology of radiographics. Ample time is allowed for demonstrations and hands-on lab exercises.

In this course the student will get prepared to demonstrate competence to perform NDT according to Radiographic Testing Procedures.

WHY STUDY RT LEVEL 3?

This course is designed for NDT personnel, operators, inspectors, technicians and professionals responsible for practical application of testing and inspection. With this course students will become better equipped to select and use the techniques and procedures at a high level. They will gain advanced knowledge of codes, standards and specifications and will do a deep dive into topics like materials, technology, equipment, and others. They acquire profound knowledge to report, interpret, evaluate and document testing results.

The RT Level 3 is designed for technicians and professionals who wish to progress their career into cutting edge RT methods with the possibility of supervision to level 1 and 2 technicians. This gives them a unique set of job opportunities in different areas, such as: consultants, leaders in the area and being responsible for inspection laboratories. They get employment in supervision or even management positions.

WHAT WILL I LEARN IN RT-3?

This course contains the following:

-

Basic Radiograhic Topics

-

Principles/Theory

-

Equipment/Materials

-

Safety and Health

-

-

Radiographic Testing

-

Techniques/Standardization

-

Interpretation/Evaluation

-

Procedures

-

-

Common Digital System Elements and Digital Image Properties

-

Digital Image Properties

-

Digital System Specific: Components

-

Digital System Specific: Image Processing Topics

-

Acquisition System Considerations

-

-

Computed Radiography

-

CR System Capabilities

-

Measuring Image Fidelity

-

Image Fidelity Indicators (System Characterization)

-

CR Technical Requirements

-

CR Technical Development

-

Use of Digital Reference Images

-

Review of DR Industry Standards

-

-

Computed Tomography

-

Advanced Theoretical Background

-

Advanced Image Processing and Algorithm Analysis

-

CT System Performance Measurements and Monitoring

-

-

Digital Radiography

-

DR System Capabilities

-

Measuring Image Fidelity

-

Image Fidelity Indicators (System Characterization)

-

Detector Selection

-

DR Image Quality Topics

-

Qualification of DR Procedures

-

Use of Digital Reference Images

-

WHAT WILL I BE ABLE TO DO AFTER TAKING THE CLASS?

-

Be aware of the different types of equipment and products available to industry with regards to radiation methods to select the proper ones to perform each specific test. Define the limitations of application of the testing method.

-

Select the proper equipment and settings, set up and calibrate RT equipment.

-

Review and supervise the work that has been done by Level 1 and Level 2 technicians.

-

Explain the theoretical background of the Method and the specific radiographic techniques.

-

Explain in detail the advantages and disadvantages of the radiographic test method and supervise others in the selection of this method.

-

Demonstrate excellent competence by detecting and characterizing flaws in components

-

Perform at a high level of performance radiographic inspections in metals, plastics and composites and translate NDT procedures into instructions adapting them to the actual working conditions.

-

Use the Xray and Gamma ray technique in locating discontinuities.

-

Supervise all tasks at, or below level 3.

-

Report the results of non-destructive tests and be able to interpret performance results according to applicable standards and procedures.

-

Write and approve inspection procedures and detailed instructions.

-

Understand and recognize the surface and sub-surface discontinuities, flaws or irregularities.

-

Understand and review the safety precautions required for radiation hazards.

-

Be able to prepare a report showing the test results.

-

Define the limitations of application of the testing method.

-

Translate NDT standards and procedures into NDT instructions adapting them to the actual working conditions.

-

Analyze the project situation and provide results required.

-

Be prepared to interpret performance results according to applicable standards, specifications or procedures.

-

They will acquire practical knowledge of applicable materials, fabrication, process, and product technology.

-

Students will get prepared to assume responsibility for a test facility.

-

Provide guidance for NDT personnel at all levels.

-

They are able to assume full responsibility for a test facility.